In our daily life we often face to Electrostatic Discharge as the rapid transfer of static electricity on the human body to another object in the form of electric current. This discharge generally do not create a negative impact on human health. However, if the object that receives the current is a sensitive equipment or dangerous material, for example a flammable substance, then the result is not so much innocent.

Electrical and electronic devices may show susceptibility against this instant and rapid discharge. ESD in the order of kilovolts, can very easily affect circuits and devices running on the order of millivolts or volts. Therefore, especially the electronic devices restricted to some specific rules are expected to show an immunity at certain level against ESD. The most widely used standard in electrical and electronic equipment, is the European Union standardEN 61000-4-2.ESD Immunity Standardorganzied under Electromagnetic Compatibility (EMC) group mainlydescribes the basic pulse shape of ESD, voltage level to be applied, application method and the test setup simulating the ESD resulting from of the operators of electrical and electronic equipment.

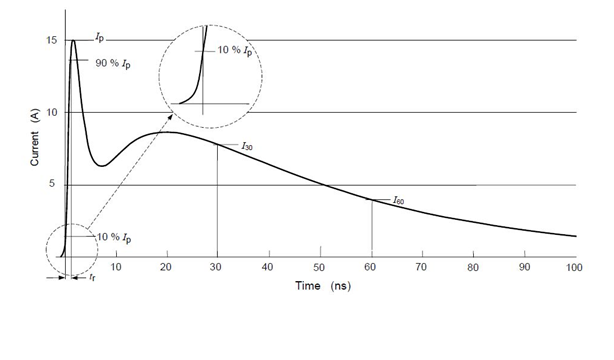

Waveform of an ESD Current (EN 61000-4-2)

In the previous article entitled “What is ESD?” it was mentioned that ESD can occur by direct contact discharge and also by air discharge caused by breakdown of the air between two different potential objects approaching each other. Accordingly ESD tests of the standards explain to perform two seperate tests as contact (touching) or air (approaching) discharge. In these tests, ESD generator simulates the body of an operator charged with static electricity and the rounded tipof the generator represents operators finger.

Portable ESD Generator

Today, considering that many electronic devices have touch screens, it is more clear to understand the importance of ESD tests, especially for end users. So how does ESD affect the electronic device? In fact, the effect can manifest itself in several different ways. First, if we consider ESD as on the order of kilovolts therefore break the insulation of air, we would not be difficult to predict the mechanical and thermal effects. Especially, in the organizationsmanufacturing electronic device or a card, the components on the card may face physical and thermalstresses and burn out if an operator touches them without any measures. ESD, by generating an electromagnetic energy around the circuit may cause sensitive circuits and components to fail by electromagnetic effects. Besides all these, ESD causing unwanted currents to flow and voltage to be induced, may directly affect the sensitive circuits. This will result as breakdown of the components, reset of the device, display faulty values or maybe completely go off.

ESD precautions should be evaluated in two categories :

Precautions to be taken in the source device or operator: The main way to prevent ESD is to prevent static electricity forming. Antistatic materials may be preferred for this. For example, to cover the floor of the working area with material that does not cause static charging, in the same way operator shoes, garments, gloves made of material which does not create static electricity is a solution. Furthermore, grounding the operator or the device potential to cause static electricity will prevent to be charged and lead the charge to flow to ground under control. The ESD wrist strap which is mandatory to wear while working is used for this purpose…

Precautions to be taken on the victim device or circuits: First, if possible, covering the vulnerable devices with antistatic material can be considered as a solution. However, it is unlikely to perform this practically.So, ESD resistant component selection, designing circuit according to the rules of EMC, efficient and proper grounding, designing filters to regions likely to face ESD or before sensitive components, and most common using varistors (MOV especially) that cuts the high voltage or current wave will lead to solutions in general.